Summary:Examples of setting up offshore manufacturing on a very limited budget

Setting up offshore manufacturing can seem intimidating and can sound expensive if you have never done it before. There are travel expenses, language and cultural differences, and a lot of unknowns. How do you go about finding a manufacturer? How do you know if you’ve found the right one? Can they build your product with the level of quality that you want? Will they make copies of your product and sell them out the back door?

These concerns can be particularly daunting for small companies with tight budgets. But setting up offshore manufacturing does not have to be expensive, and a lot of the unknowns and uncertainties can be eliminated if you work with somebody who has been there before and knows the lay of the land.

Clint has helped some very small businesses set up offshore manufacturing, including businesses that were started and self-funded by individuals. Clint’s familiarity with offshore manufacturing, particularly in China, helps pave the way for a fast, efficient production ramp. Clint can find and qualify the right manufacturer; set up a manufacturing agreement; and help you get tooled up very quickly.

The inevitable question is, “How small a budget are you talking about?”

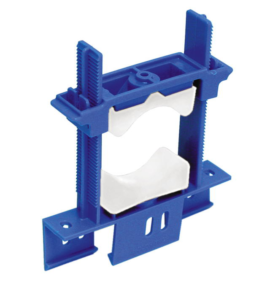

The inevitable answer is, “It depends on the complexity of the product.” The product photos shown in this case study are examples of very low-cost production ramp-ups in China. Each of these required only one or two trips to China by Clint, and the NREs to start up production (tooling, fixtures, jigs, sample runs) were only a few thousand dollars. For each of the product photos shown in this case study, the total expense to get production started was less than $10,000.

The inevitable answer is, “It depends on the complexity of the product.” The product photos shown in this case study are examples of very low-cost production ramp-ups in China. Each of these required only one or two trips to China by Clint, and the NREs to start up production (tooling, fixtures, jigs, sample runs) were only a few thousand dollars. For each of the product photos shown in this case study, the total expense to get production started was less than $10,000.

This is not typical – these products represent the low end of the cost curve for ramping up offshore production. As products grow in complexity, the cost of setting up production grows accordingly.

It’s worthwhile to keep the following in mind:

When you set up offshore production there will be travel expenses and engineering expenses, but the payback can be very quick. The lower cost of tooling usually offsets more than 50% of those expenses, and the cost savings on your first couple of production orders generally offsets the remainder of the expenses. For many products, by the time you place your second or third mass-production order, you have offset all of the up-front expenses for going abroad, and you begin to reap a net savings from offshore manufacturing.

If you would like to get an estimate of how much it would cost to set up offshore manufacturing, please contact Clint.